- Solutions

- Case studies

- Company

- Career

Share case study:

Pressure sintering technology plays a central role in toolmaking as well as in mechanical and plant engineering. For example, indexable inserts and carbide drills are manufactured in toolmaking, while gear wheels, hydraulic components and non-porous structural parts are produced in mechanical engineering.

The process requires pressures of 60 to 100 bar and temperatures of up to 1500 °C, and the debinding and sintering processes often have to take place in the same chamber. A uniform gas flow and temperature homogeneity are crucial in order to achieve high-quality results.

In addition, companies face challenges such as high energy requirements, limited life cycles for system components and increasing demands for sustainability and resource efficiency.

Industry:

Procedure:

Solution:

Services:

Consulting, engineering technical documentation, manufacturing

Result:

High-temperature processes in pressure sintering systems require an insulation cylinder that remains permanently stable and gas-tight, even with extreme pressure and temperature changes.

This means the highest demands on the insulation properties of the cylinder to ensure safe and reproducible processes.

For a long time, it was also a particular challenge for the pressure sintering industry to procure large, one-piece insulation cylinders. It is not uncommon for the industry to require insulation systems over 3 meters in length. Only a few manufacturers worldwide were able to produce one-piece cylinders of this size.

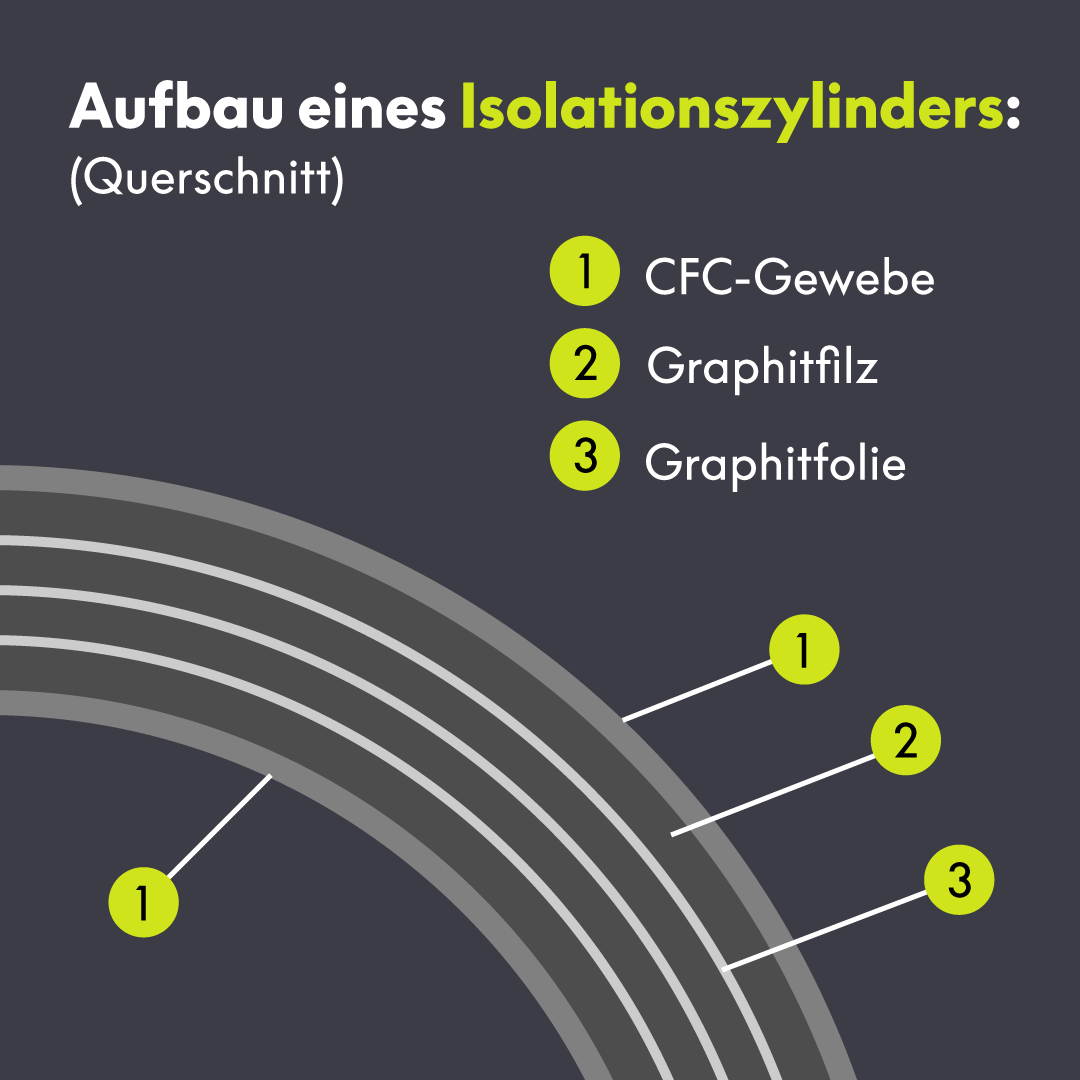

Graphite Materials took the initiative and, together with a business partner, developed an insulation cylinder in sandwich construction that was specially tailored to the application.

Testing of the prototype was successful and the cylinder met all mechanical and thermal requirements.