- Solutions

- Company

- Career

A huge transformation is taking place in today’s automotive world. Electric cars, stricter emissions regulations and the desire for more efficient vehicles are driving the industry forward. However, one of the biggest challenges remains, the development and manufacturing of modern transmissions. This is where traditional engineering expertise meets the requirements of new, sustainable mobility.

Read here how Graphite Materials was able to help find a value-adding and reliable solution.

Share case study

Industry:

Automobile

Procedure:

Low-pressure carburizing with high-pressure gas quenching

Solution:

Services:

Result:

Significant improvement in the cases of the distortions

The following challenges are requested to be considered:

By a comprehensive analysis of the existing process, we identified various possibilities for optimization.

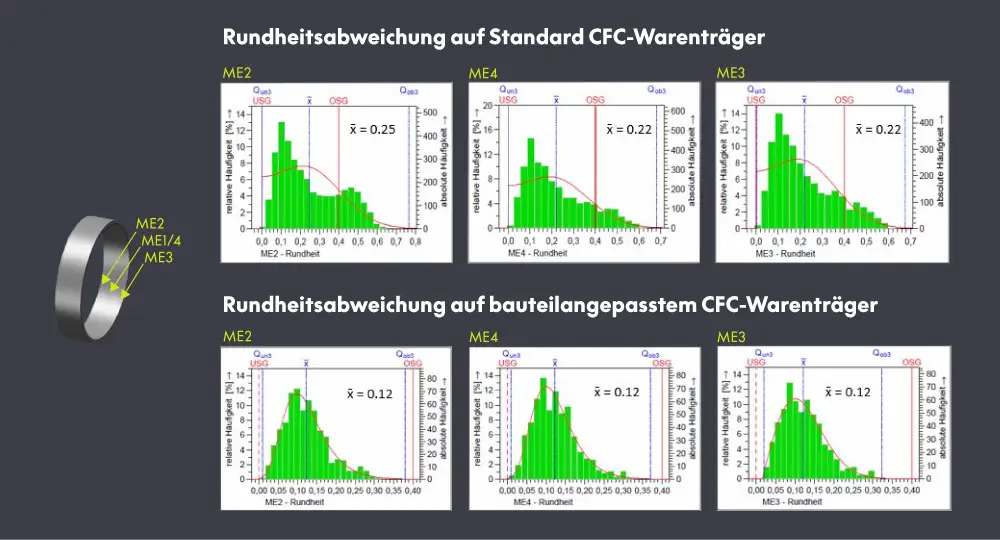

The positioning of the rings has been redesigned. In a series of tests, In a series of tests, 700 rings from four different batches were measured and evaluated after heat treatment on the optimized carrier. The shape and dimensional deviations were all within the required tolerances.

According to the optimized fixture design, the maximum values of the roundness deviation were reduced by 25 % and the average deviation by 50 %.

Not a single ring had to be declared as a reject.

The new fixture design was approved for series production and implemented as a new standard.