- Solutions

- Case studies

- Company

- Career

Ideal for customised solutions

Alongside diamond, graphite is one of the natural modifications of the chemical element carbon (C) and is characterised by its typical hexagonal crystal structure. In addition to natural graphite, there are synthetic variants that are produced using special manufacturing processes and used in numerous industrial applications.

Synthetic graphite is produced by coking and then graphitising carbons (e.g. coke). Coarse-grained coke is ground and mixed with binders (e.g. pitch). The material is moulded using processes such as extrusion, vibration compaction or isostatic pressing. The material has the characteristic hexagonal crystal structure.

The shaping processes determine the properties of different types of graphite:

Extruded graphite

Is produced in round or rectangular shapes using the extrusion process. The maximum grain size is 0.8 mm, and the material properties are direction-dependent (anisotropic).

Vibration molded graphite

Round or rectangular shapes are produced by vibration and uniaxial pressure. The grain size is 0.3-0.5 mm and the properties are mostly direction-independent (isotropic).

Isostatic graphite (iso-graphite)

Is densified in a cold isostatic press (CIP) from particularly fine-grained powder (15-30 µm). This method produces an isotropic property profile with high flexural strength (approx. 50 MPa) and a high level of purity.

All variants of synthetic graphite share common properties:

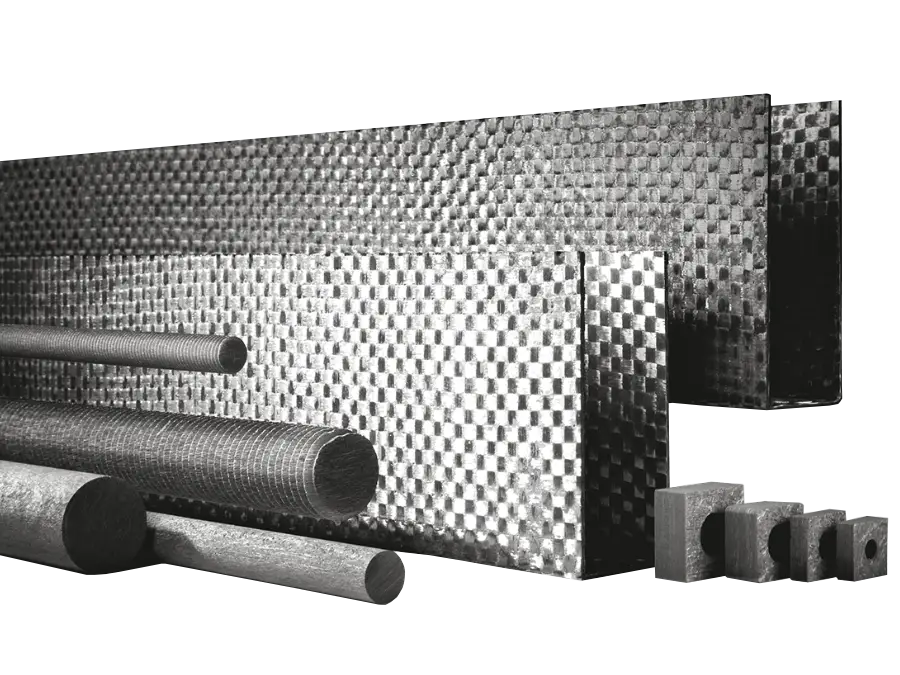

Carbon fibre reinforced carbon (CFC) is a high-strength composite material consisting of carbon fibres embedded in a carbon or graphite matrix. This material is characterized by exceptional mechanical properties, high temperature resistance and low thermal expansion.

The variety of CFC materials results from different carbon fibre types, the processing into fabrics or meshes, and the choice of matrix.

The production of CFC requires several steps:

The shape is created by processes such as hand laminating, hot pressing or winding for sheets and tubes. Precise molded parts can be produced by CNC machining or other mechanical processes.

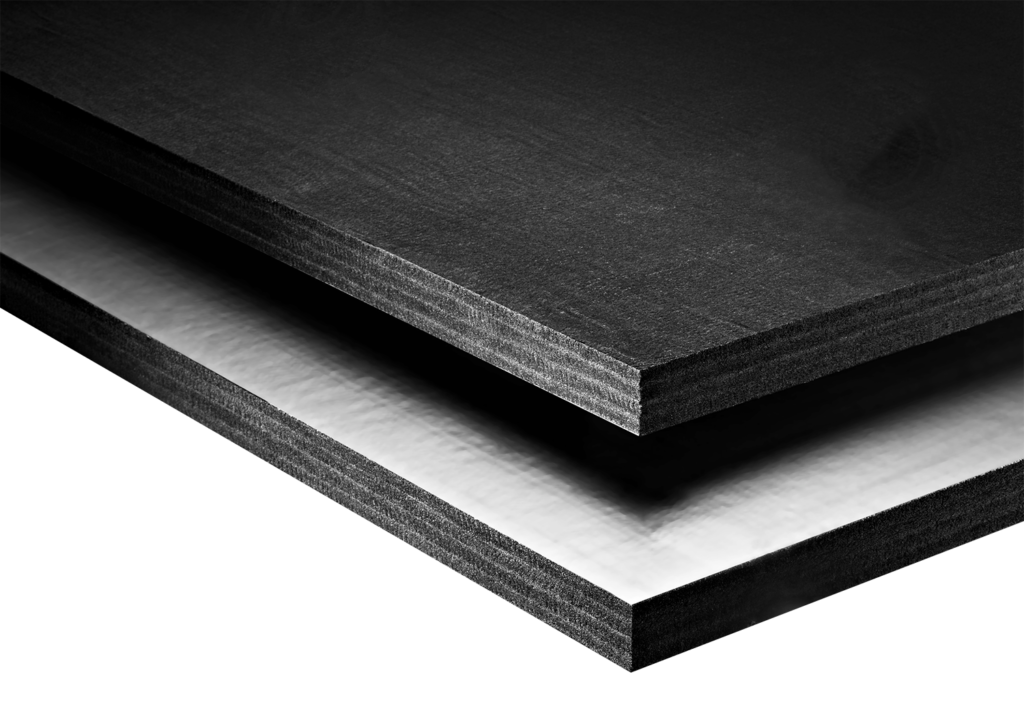

Carbon and graphite soft felts are made of carbon fibres and are characterized by exceptional thermal, electrical and chemical properties.

They are varied and particularly suitable for high-temperature and special applications.

The production of soft felts requires several steps:

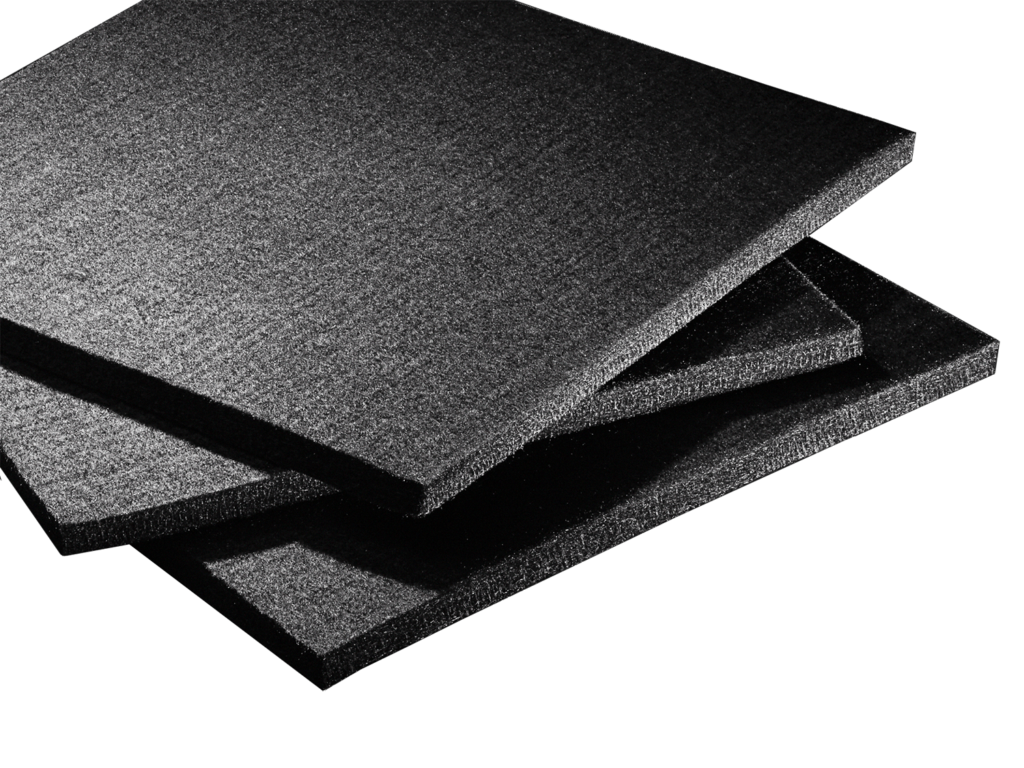

Rigid felts are dimensionally stable insulation materials made of carbon fibres that are characterized by low thermal conductivity and high temperature resistance.

They are particularly suitable for applications in oxygen-free atmospheres and vacuum environments at temperatures above 800 °C.

The production of rigid felts requires several steps:

The binding agent ensures that the fibers are reliably fixed in the material. Hard felts are usually produced as sheets, blocks or cylinders, but can be shaped into other geometries by mechanical processing.

To improve surface resistance, graphite coatings, CFC fabrics or graphite foil can be applied to protect the felt from mechanical damage or chemical attack.

Rigid felts share many properties with soft felts, but have additional advantages:

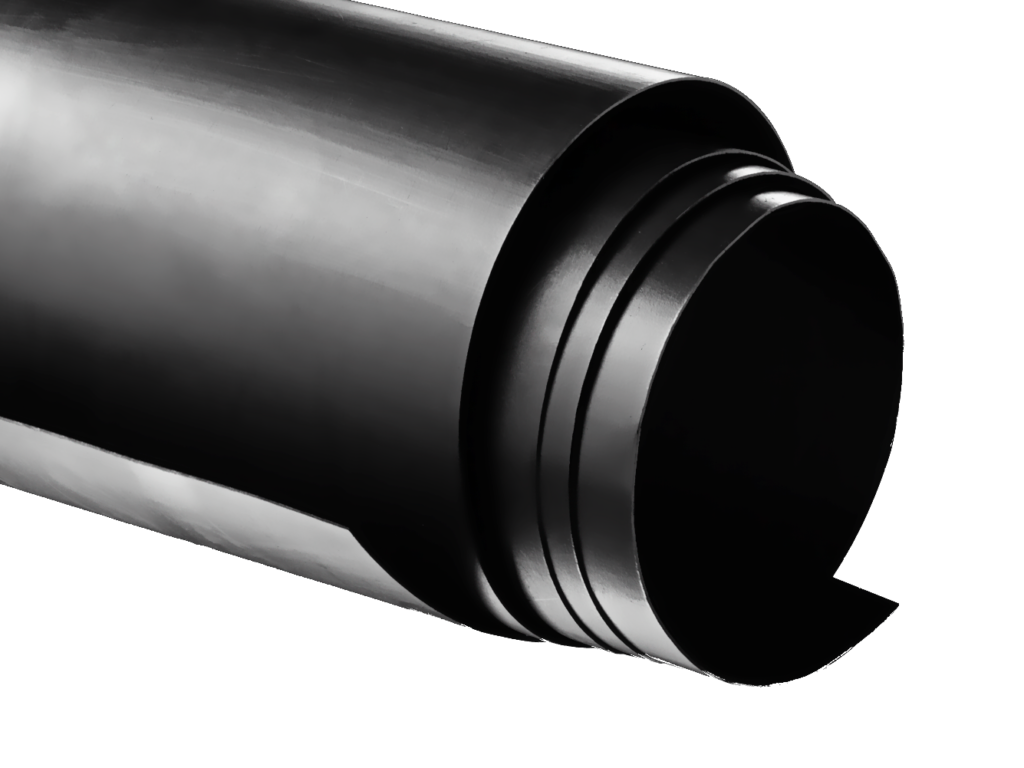

Graphite foil is a material made from natural graphite is produced. After intensive cleaning, the flaky raw material is thermally treated and then rolled into films or sheets.

This compression process creates an anisotropic structure with direction-dependent properties.

Graphite foil is flexible, compressible and can be easily cut, punched or embossed. It can also be combined with other materials by rolling or gluing to create composite materials with improved properties.