Progress through temperature control

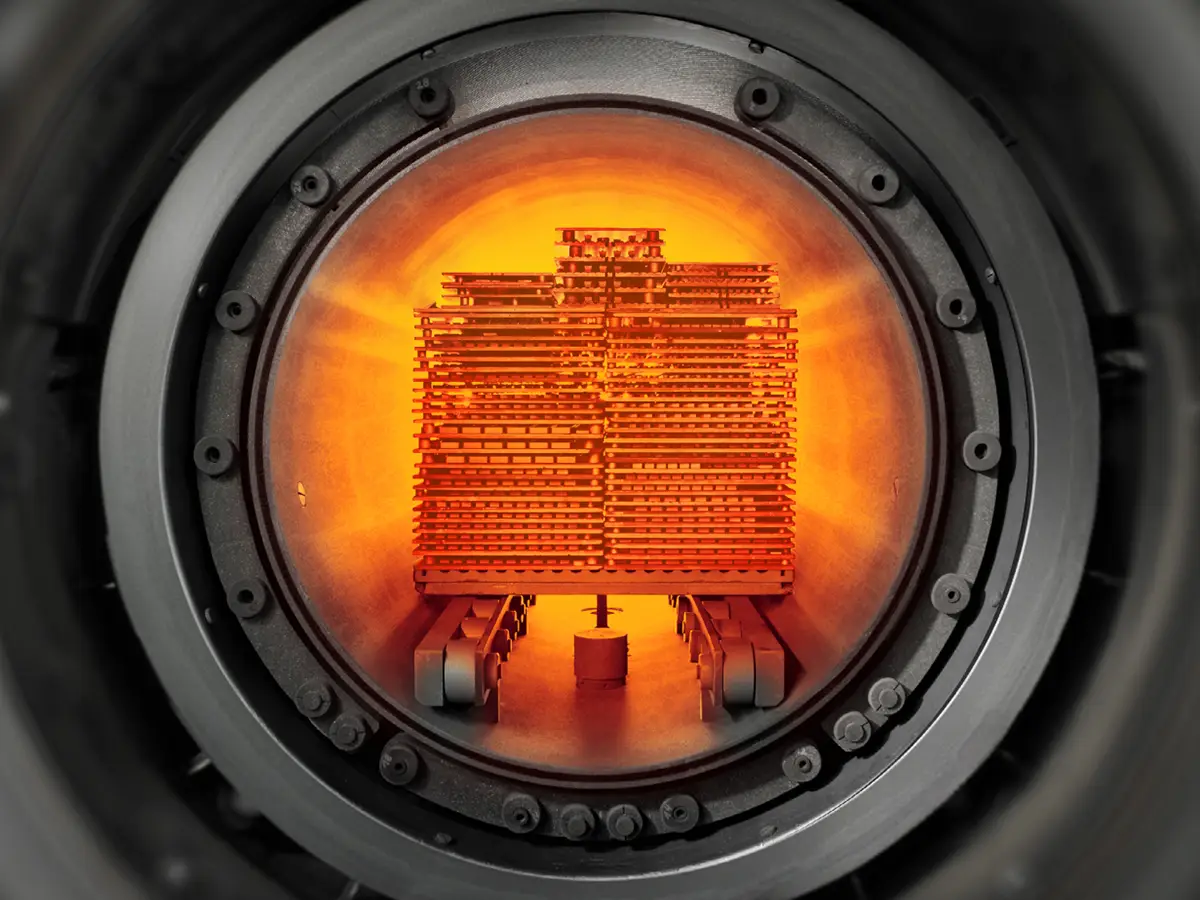

Heat treatment processes such as hardening, annealing or carbonizing are essential for modifying material properties in a targeted manner. These processes usually take place in high-temperature furnaces at temperatures between 800 and 1,200 °C – often under vacuum or in oxygen-free inert gas atmospheres such as argon or nitrogen. Controlled temperature management is crucial to produce optimal material structures.

But as demands on material properties increase, so do the demands on the efficiency and precision of heat treatment plants. This is where graphite comes into play: as a high-performance material, it has become indispensable for modern heat treatment processes.

Graphite: hidden champion of high-temperature technology

Graphite has a unique combination of properties that make it ideal for extreme conditions:

- High temperature resistance: Graphite remains stable even at temperatures above 2,500°C.

- Low thermal expansion: This minimizes material stresses and ensures high process accuracy.

- Excellent thermal conductivity: This enables even temperature distribution and improves the efficiency of the heat treatment.

- Chemical resistance: Graphite hardly reacts with process gases or metals, thus preventing contamination.

Graphite in heat treatment – where is it used?

In modern heat treatment plants, graphite plays a central role in the following functions:

- Heating elements and shielding: graphite heating elements enable precise temperature control and homogeneous heating of the workpiece.

- Insulation materials made of soft and hard felts: they reduce heat loss and ensure a stable temperature distribution in the furnace.

- CFC charging racks: Carbon fiber-reinforced carbon (CFC)

offers high mechanical stability at a low weight – essential for the safe handling of components in the furnace

- Graphite gas flow elements:

These optimize the atmosphere in the furnace, thus improving heat transfer and quenching processes.

Focus on sustainability and efficiency

Modern heat treatment plants are increasingly relying on sustainable solutions. Graphite contributes to this by reducing energy consumption, increasing process stability and ensuring a long service life for components. The reusability of graphite materials and advances in recycling technology also help to conserve valuable resources.

Without highly developed materials such as graphite, the precise heat treatment that makes modern high-performance components possible would be inconceivable. Its exceptional properties not only enable precise process control, but also contribute to greater energy efficiency and sustainability. In a world where material performance determines innovative strength, graphite remains an irreplaceable element for advanced heat treatment technology.