- Solutions

- Case studies

- Company

- Career

Share case study

Without the use of ultra-thin layers, most modern technologies would not be possible.

For example, touchscreens on displays only work because transparent, conductive layers are applied to the glass. In solar cells, special coatings ensure that light can be efficiently converted into electricity, and semiconductors are also finely coated in the production of microprocessors and memory chips.

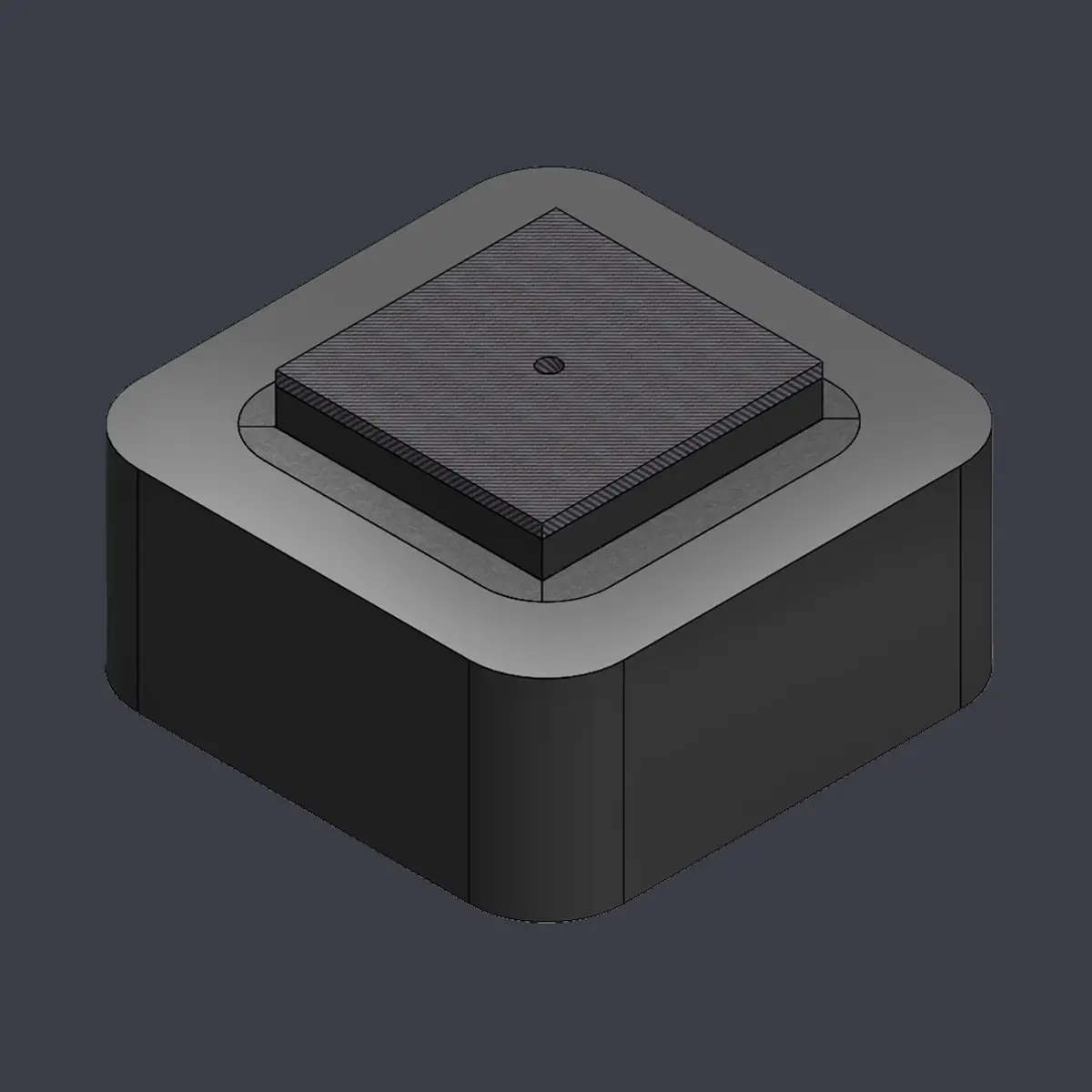

The production of sputtering targets is a technically high-precision process.

The starting material often consists of a mixture of different powders that are required for the final properties of the target. The powder is filled into an electrically conductive mold (e.g. square plate) and compacted under uniaxial pressure and temperature (Joule heat due to electrical energy). The powder is thus sintered into a solid, in this case a plate, and solidified.

Industry:

Tool, mold and machine construction

Procedure:

Pressure Sintering

(Field-Assisted Sintering Technique/ Spark Plasma Sintering)

Solution:

Services:

Analysis and simulation, new design, production of sintered moulds

Result:

Increased process stability, quality and reliability as well as output per oven run

When it comes to the mechanical stability of the targets, the high thermal and mechanical loads on the mould pose a particular challenge. The mould can crack or warp. For this reason, the powder mould should be designed to be able to absorb induced mechanical and thermal stresses without cracking (multiple use). Likewise, no powder, which is entirely required for the output of the targets, should be lost as a result of pressing via gaps that are required for the demouldability of the target from the mould.

In addition, the raw materials used are extremely expensive and disruptions or interruptions to the process represent a high cost factor.

Process reliability and optimisation, durability and sustainability in recycling at the end of the life cycle are further key challenges.

In the example discussed here, the previous sintering mould could not withstand the pressure caused by the uniaxial pressing – it burst during the furnace run.

The following targets were set for optimisation:

Sintering mold overloaded

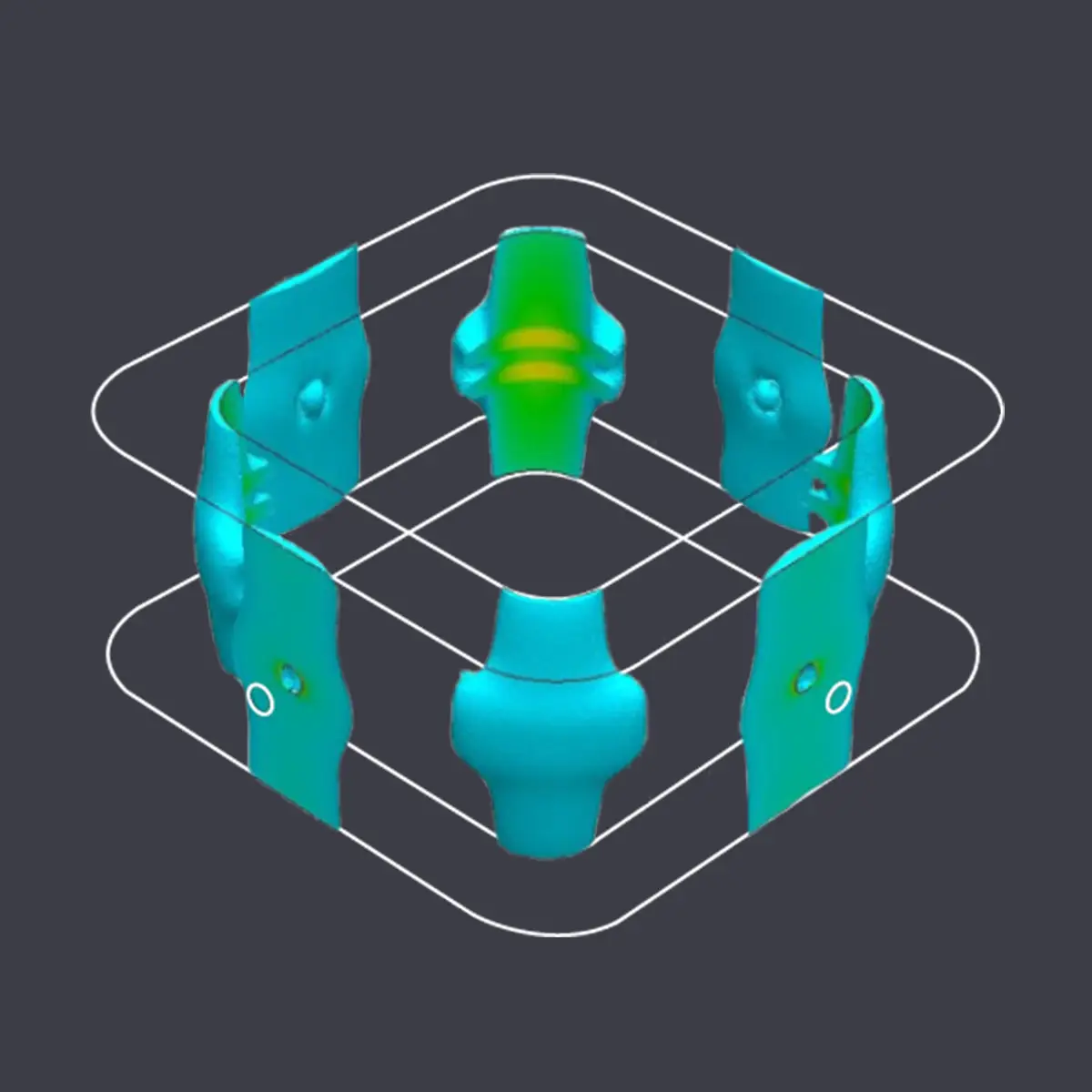

We carried out a FEM simulation on the basis of the data supplied by the customer and the specified framework conditions such as temperature and pressure. We were able to determine that changing the inner corner radii was the best option for improving the shape.

The proposed changes meant that there were no more cracks in the mould and therefore no interruptions in the production process.

The optimisation was achieved without increasing the mass of the mould.

This made the change cost-efficient and effective.

Sintering form optimized

By changing the inner radius, the stresses in the mould could be reduced by 50 %.

The optimization of the mould contour led to a safe and stable process with multiple use of the mould. The material output of the targets was increased by optimizing the gap dimensions, thus increasing the added value.